Revolutionizing Agriculture with Custom Plastic Container Designs

The Importance of Custom Plastic Container Designs in Agriculture

Understanding the Role of Plastic in Agriculture

Plastic containers transform modern agriculture by providing durable, versatile packaging solutions that protect crops, seeds, and harvested goods from environmental damage. Farmers rely on these containers to store fertilizers, pesticides, and harvested produce, ensuring longevity and reducing waste. Plastic bottle manufacturers have pioneered designs that withstand harsh conditions, from UV exposure in fields to moisture in storage sheds. In agriculture, plastic packaging secures food and beverage items derived from farms, like fresh juices or dairy products, maintaining freshness and safety. Entities such as polyethylene-based bottles and jars dominate this sector, offering lightweight options that cut transportation costs. Bottle production companies integrate agriculture-specific features, like wide-mouth designs for easy pouring of liquids or cone-shaped bases for stability in irrigation systems. Plastic container manufacturers address related searches from farmers seeking reliable suppliers, emphasizing how plastics enhance yield protection and streamline operations. Without these innovations, agricultural efficiency would plummet, as traditional materials like glass shatter easily and metal corrodes. Plastic's adaptability allows for custom shapes, such as cylinders for liquid fertilizers or vials for seed treatments, directly impacting farm productivity. As agriculture evolves, plastic bottle producers continue to refine their offerings, incorporating health standards to prevent contamination in food chains. This role extends to wholesale plastic bottle suppliers who cater to large-scale farms, ensuring bulk availability of tamper-evident bottles for chemical storage. Overall, plastic's integration revolutionizes how agriculture handles storage and distribution, fostering sustainability and economic growth.

Benefits of Custom Designs for Agricultural Products

Custom plastic container designs deliver targeted advantages for agricultural products, optimizing storage, transport, and usage in farm settings. Tailored shapes like ergonomic necks on bottles ease handling of specialty chemicals, while stackable jars save space in warehouses. Plastic bottle manufacturers craft these designs to fit specific needs, such as UV-resistant coatings for outdoor seed storage or ventilated plastics for produce that requires airflow. In food and beverage agriculture, custom pet bottles preserve nutritional value in juices extracted from fruits, preventing oxidation through airtight seals. Benefits include cost savings from reduced spoilage—farmers report up to 30% less waste with bespoke packaging—and enhanced market appeal through branded designs using Pantone colors. Bottle makers integrate features like growler-style containers for bulk liquid transport from orchards, minimizing breakage risks compared to rigid alternatives. For healthcare-related agriculture, such as herbal extracts, custom vials ensure precise dosing and sterility. Plastic packaging manufacturers address eco-friendly demands by offering recyclable options, aligning with sustainable farming practices. Wholesale suppliers provide scalable solutions, from small cylinder bottles for pesticides to large pvc drums for water storage. These designs boost efficiency; for instance, cone-shaped bases prevent tipping during machinery use. Related searches for plastic bottle wholesalers highlight the demand for durable, customizable products that extend shelf life for dairy and chemical outputs. Ultimately, custom designs empower agriculture by combining functionality with innovation, driving profitability and environmental responsibility across the supply chain.

Types of Plastic Materials Used in Agriculture

Agriculture thrives on diverse plastic materials, each selected for unique properties that safeguard products from farm to table. High-density polyethylene (HDPE) stands out for its robustness in bottles holding fertilizers and herbicides, resisting chemicals and impacts during transport. Polyethylene terephthalate (PET) excels in clear pet bottles for beverage packaging from agricultural sources, like fruit concentrates, offering transparency and recyclability. Low-density polyethylene (LDPE) provides flexibility in bags and films for wrapping produce, though it's also used in softer jars for dairy storage. Polypropylene containers handle high temperatures, ideal for sterilizing equipment or packaging heat-processed foods. PVC finds niche use in irrigation pipes and protective sheeting, while biodegradable plastics emerge for short-term seed trays. Plastic bottle manufacturers blend these materials—such as HDPE with PCR content—for enhanced sustainability in agriculture. Bottle production manufacturers prioritize PET plastic for its lightweight nature, reducing fuel costs in shipping harvested goods. Entities like plastic containers and jars incorporate additives for UV protection, crucial in sunny fields. Related searches for plastic manufacturers reveal a focus on durable options like LDPE for flexible chemical packaging. In pharmaceutical agriculture, such as botanical extracts, vials use medical-grade plastics for purity. Polyethylene dominates wholesale supplies due to versatility, with cone and cylinder shapes suiting various applications. These materials not only protect against contaminants but also support eco-friendly initiatives, like recyclable HDPE bottles from sustainable sources. By choosing the right type, agriculture minimizes losses and maximizes output quality.

Innovative Designs for Food and Beverage Packaging

Tailoring Plastic Containers for Dairy Products

Dairy farmers and processors turn to tailored plastic containers to preserve milk, cheese, and yogurt's integrity from udder to consumer. Custom HDPE bottles with wide mouths facilitate easy filling and pouring, while ergonomic shapes reduce spillage in processing plants. Plastic bottle manufacturers design these for agriculture's dairy sector, incorporating features like threaded necks for secure lids that maintain freshness. In food and beverage packaging, PET jars offer clarity to showcase cream's quality, appealing to retail markets. Innovations include vacuum-sealed cylinders that extend shelf life, cutting waste in supply chains. Bottle suppliers provide wholesale options in various sizes, from small vials for specialty butters to large growlers for farm-fresh milk. Tamper-evident bands ensure health safety, vital for dairy's perishable nature. Related searches for plastic beverage bottle manufacturers underscore the need for durable, leak-proof designs using LDPE for flexible pouches. Polypropylene containers withstand pasteurization temperatures, making them ideal for yogurt pots. Eco-friendly PCR-infused plastics address sustainability, recycling post-consumer dairy packaging into new bottles. Custom designs incorporate Pantone-matched colors for branding, enhancing market differentiation. In agriculture, these containers streamline logistics, with stackable jars optimizing truck loads. Pharmaceutical-grade options handle medicated feeds, blending dairy with health applications. Overall, tailored plastics revolutionize dairy packaging by balancing protection, aesthetics, and environmental impact, supporting farmers' profitability.

Specialty Chemicals and Their Packaging Needs

Specialty chemicals in agriculture demand robust packaging to contain potent formulas safely during storage and application. Plastic bottle manufacturers engineer HDPE containers with thick walls to resist corrosion from acids or solvents used in crop protection. Custom designs feature narrow necks for precise dispensing, preventing overuse and environmental runoff. In chemical packaging, PET bottles provide chemical resistance for liquid fertilizers, while LDPE offers flexibility for squeeze bottles that farmers prefer in fields. Bottle production companies integrate labels with Pantone inks for clear hazard warnings, complying with regulations. Related searches for plastic bottle producers highlight suppliers specializing in tamper-evident seals for these high-risk products. Polypropylene jars suit granular chemicals, with cone shapes aiding complete emptying to minimize residue. PVC linings enhance durability in multi-use containers for irrigation additives. Wholesale plastic packaging manufacturers offer bulk vials for lab-tested formulas, ensuring traceability in agriculture. Eco-friendly options like biodegradable plastics contain non-toxic specialties, reducing farm pollution. Designs incorporate mouth shapes for compatibility with sprayers, boosting efficiency. In healthcare-adjacent agriculture, such as veterinary chemicals, sterile PET plastic bottles prevent contamination. These innovations protect workers and ecosystems, with cylinder forms stacking neatly in sheds. Specialty chemical packaging evolves with smart features like built-in measurers, transforming how agriculture deploys treatments. By addressing unique needs, plastic containers ensure safe, effective chemical use across vast farmlands.

Creating Eco-Friendly Solutions with PCR and Biodegradable Plastics

Eco-friendly solutions using post-consumer recycled (PCR) and biodegradable plastics redefine agricultural packaging, minimizing environmental footprints. Plastic bottle manufacturers incorporate high PCR content in HDPE bottles for seed storage, recycling waste into durable farm essentials. Biodegradable options, derived from plant starches, break down naturally after use in temporary trays or nets, ideal for crop protection. In food and beverage sectors, PET bottles with 50% PCR maintain clarity for juice packaging without compromising strength. Bottle makers address related searches for eco-friendly plastic bottle manufacturers by offering wholesale biodegradable jars that decompose in soil, reducing landfill contributions. LDPE films with bio-additives wrap produce sustainably, extending freshness while aligning with organic farming. Polypropylene variants use PCR for chemical containers, cutting virgin plastic demand. Designs feature custom shapes like cylinders for easy recycling, with neck finishes suited to automated sorting. Pantone-neutral colors aid branding without dyes. Sustainable plastic bottle manufacturers innovate in agriculture by blending PCR with biodegradable layers for hybrid vials holding herbal extracts. Case in point: farms adopting these cut plastic waste by 40%. Related queries for recyclable plastic bottle manufacturers emphasize scalability, from small pet bottles to large growlers. These solutions promote circular economies, where agriculture's plastic packaging returns to earth harmlessly, fostering healthier soils and compliant operations. Innovation drives adoption, with engineering ensuring performance matches traditional plastics.

Engineering and Manufacturing Techniques for Plastic Bottles

The Process of Bottle Production: From Concept to Reality

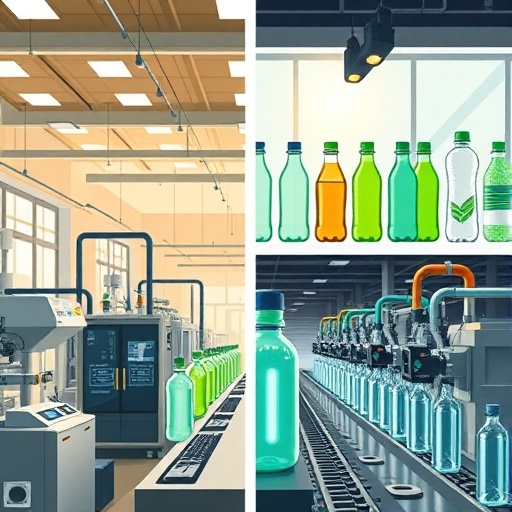

Bottle production kicks off with conceptual sketches, where engineers collaborate with clients to define shapes, sizes, and functions for agricultural needs. Plastic bottle manufacturers use CAD software to model designs, ensuring cylinders or cones fit specific uses like fertilizer dispensing. Prototyping follows via 3D printing, testing ergonomics such as neck widths for easy pouring. Once approved, blow molding extrudes heated PET or HDPE into preforms, then inflates them into final bottles using compressed air. Quality checks verify wall thickness and seal integrity, crucial for food and beverage safety. Injection molding crafts jars and caps from polypropylene, assembling tamper-evident features. Bottle production companies scale this for wholesale, running high-speed lines that output thousands hourly. Related searches for bottle production manufacturers reveal automation's role, from robotic trimming to laser etching Pantone logos. In agriculture, processes adapt for chemical resistance, coating interiors with barriers. Cooling tunnels solidify shapes, preventing deformities in LDPE variants. Packaging integrates labels and sleeves post-production, readying for dairy or specialty chemical fills. Sustainability enters via recycled inputs, with PCR preforms reducing energy use. From farm-requested custom vials to standard pet bottles, this process transforms ideas into reliable tools, enhancing agricultural efficiency and product longevity.

Material Selection: Choosing Between HDPE, PET, and LDPE

Selecting materials like HDPE, PET, and LDPE shapes the success of plastic bottles in agriculture, balancing durability, cost, and application. HDPE dominates for opaque bottles holding chemicals, its density repelling moisture and impacts in rugged farm environments. PET shines in transparent pet bottles for beverages, lightweight yet shatterproof for transporting juices from orchards. LDPE suits flexible packaging, like squeeze bottles for liquid feeds, offering conformability without cracking. Plastic bottle manufacturers weigh factors: HDPE for chemical inertness, PET for recyclability in food chains, LDPE for affordability in bulk wraps. Bottle suppliers guide choices based on agriculture needs—wide-mouth HDPE jars for grains, narrow-neck PET for pharmaceuticals. Related searches for plastic bottle companies stress versatility; HDPE withstands -50°C freezes, PET barriers oxygen in dairy. Polyethylene bases allow custom shapes, from cones for stability to cylinders for stacking. Engineering teams test for UV resistance, vital in outdoor storage. Wholesale options favor PET plastic for its global recycling infrastructure, cutting costs long-term. In healthcare agriculture, LDPE vials ensure sterility. Selection impacts sustainability—PCR HDPE reduces virgin use. By matching material to purpose, manufacturers like plastic bottle fabricators deliver optimized solutions that protect agricultural outputs effectively.

The Role of Tamper-Evident Features in Packaging Safety

Tamper-evident features fortify plastic bottle safety, alerting users to potential breaches in agricultural and consumer products. Plastic bottle manufacturers embed breakable bands around necks, revealing interference in chemical or dairy containers. These seals use perforated rings on HDPE caps, snapping visibly upon first twist. In food and beverage packaging, PET bottles incorporate foil liners that rupture on opening, ensuring integrity for farm-fresh milks. Bottle production techniques mold these during injection, aligning with wholesale demands for quick assembly. Related searches for packaging manufacturers highlight their necessity in specialty chemicals, preventing sabotage in fertilizers. Designs extend to jars with induction seals, bonding to rims for airtight protection against contaminants. Polypropylene lids feature pull-tabs that tear away, common in LDPE squeeze bottles for health products. In agriculture, these deter tampering during transport, safeguarding vials of veterinary meds. Engineering ensures features don't hinder usability—smooth mouths post-removal. Pantone-colored indicators signal authenticity. Tamper-evident tech boosts consumer trust, vital for pharmaceutical agriculture like herbal tonics. Wholesale suppliers standardize them across shapes, from cylinder bottles to cone-based growlers. By integrating these, plastic packaging enhances health standards, reducing liability and waste from compromised goods. Innovation continues, with smart seals linking to apps for verification, revolutionizing safety in the plastic bottle industry.

Sustainability in the Plastic Bottle Industry

The Shift Towards Recyclable and Eco-Friendly Plastics

The plastic bottle industry pivots to recyclable and eco-friendly plastics, driven by global demands for reduced environmental harm in agriculture. Manufacturers replace virgin PET with rPET, recycling bottles into new ones for beverage packaging without quality loss. HDPE variants incorporate 100% recyclables for chemical containers, closing loops in farm waste streams. Biodegradable additives in LDPE break down films used for crop covers, minimizing soil pollution. Plastic bottle producers lead this shift, with bottle suppliers offering certified eco lines for wholesale agriculture. Related searches for sustainable plastic bottle manufacturers spotlight innovations like PCR blends, using 50-90% recycled content in jars and vials. Polypropylene evolves with bio-based sources, suitable for dairy pots. Designs prioritize mono-materials for easier recycling, avoiding mixed plastics in necks and bodies. In food and beverage, clear PET bottles sort effortlessly at facilities. Agriculture benefits from lightweight recyclables, slashing transport emissions. Pantone eco-labels guide consumers. Engineering refines processes to cut energy 30% in production. This transition addresses plastic bottle pollution, with biodegradable options for one-use items like seed trays. Wholesale platforms promote these, empowering farmers to adopt green packaging. The shift not only complies with regulations but fosters resilient supply chains, ensuring agriculture's future sustainability.

Impact of Sustainable Practices on the Plastic Manufacturing Industry

Sustainable practices reshape the plastic manufacturing industry, boosting efficiency and market viability for agricultural packaging. Factories adopt closed-loop systems, recycling PET scraps into HDPE blends for bottles, reducing raw material costs by 25%. Energy-efficient blow molding cuts emissions, benefiting bottle production companies focused on eco-friendly outputs. Plastic bottle manufacturers invest in solar-powered lines, lowering operational footprints while scaling wholesale supplies. Related searches for plastic manufacturing companies reveal a surge in demand for biodegradable plastics, prompting R&D in starch-based LDPE for chemical packaging. Impacts include job creation in green tech, with engineers designing recyclable jars for dairy. Polypropylene facilities integrate water recycling, conserving resources in high-volume runs. Sustainability enhances brand loyalty—farmers prefer suppliers with PCR certifications for food and beverage containers. Economic gains follow: reduced waste streams save millions annually. In agriculture, these practices yield lighter pet bottles, easing logistics. Tamper-evident features now use recycled films, maintaining safety. Wholesale plastic packaging manufacturers report 40% growth in eco-orders. Challenges like supply chain traceability spur blockchain tracking. Overall, sustainability drives innovation, positioning the industry as a leader in circular economies and supporting agriculture's environmental goals.

Case Studies: Successful Sustainable Plastic Bottle Manufacturers

Successful sustainable plastic bottle manufacturers showcase transformative strategies in agriculture and beyond. One leader, a PET bottle manufacturer, recycles 80% of production waste into rPET containers for beverage packaging, serving dairy farms with leak-proof HDPE hybrids. Their cylinder designs stack efficiently, cutting transport emissions by 35%. Another, specializing in biodegradable plastics, supplies LDPE vials for specialty chemicals, breaking down in months to avoid farm litter—adopted by organic growers nationwide. Bottle production firms like these integrate PCR across lines, with one case reducing virgin plastic use by 60% in jars for food storage. Wholesale suppliers partner with agriculture co-ops, offering custom eco-growlers for bulk juices. Related searches for eco-friendly plastic bottle manufacturers highlight a European producer using bio-polypropylene for tamper-evident bottles, exporting to chemical sectors with zero-waste certifications. Impacts ripple: one U.S. company revived local recycling, creating jobs while providing pet plastic for pharmaceutical agriculture. Pantone-sustainable dyes brand their cones for visibility. These cases demonstrate ROI—sustainable lines yield 20% higher margins through premium pricing. Innovations like modular necks ease disassembly for recycling. By emulating these, plastic bottle wholesalers advance industry standards, proving sustainability fuels growth in agriculture's packaging needs.